In-house Services

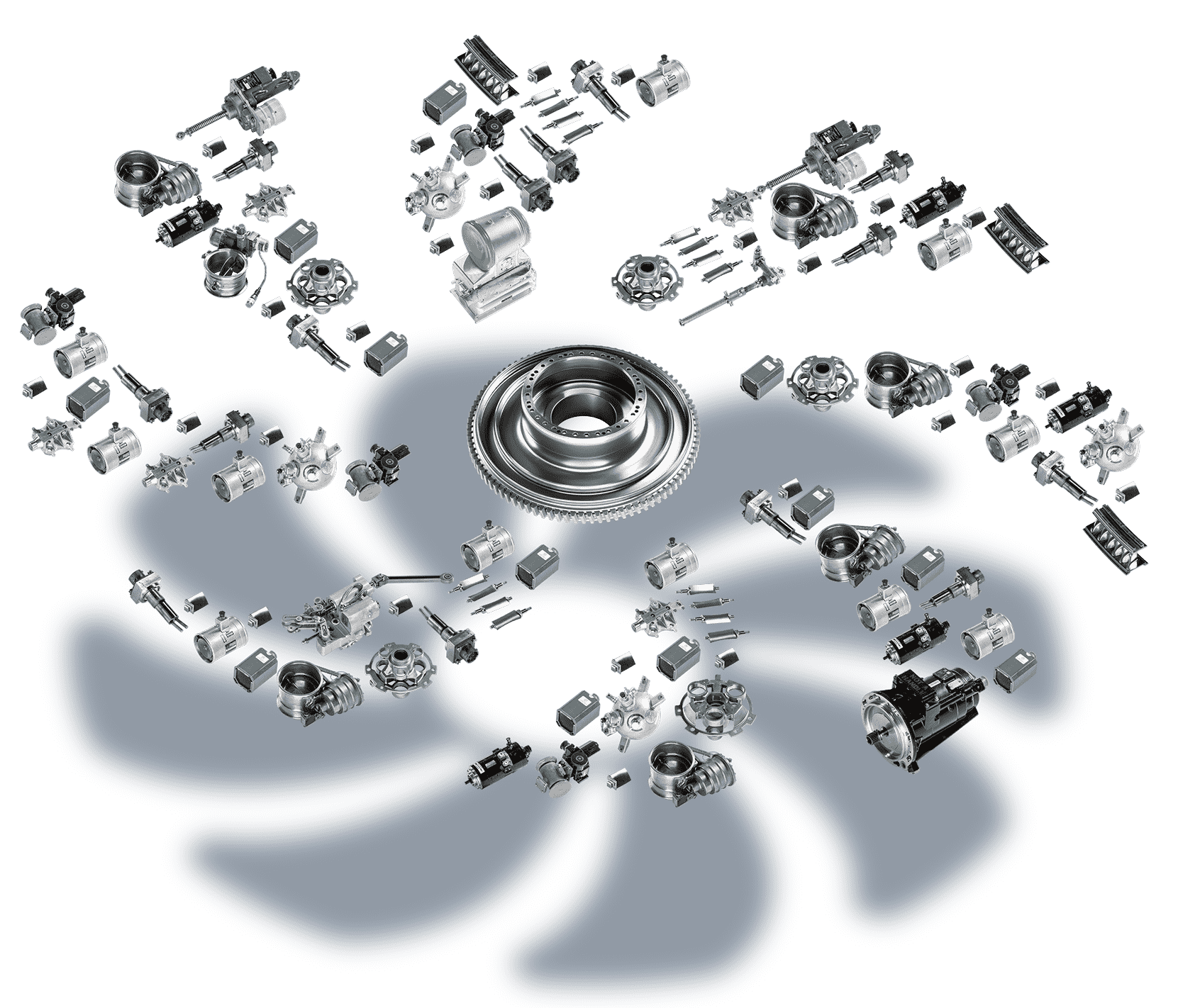

Engine maintenance solutions, including hospital and quick-turn activity.

Off-wing Services

A range of innovative solutions including one-stop wing/airport remote service offering engine transition support.

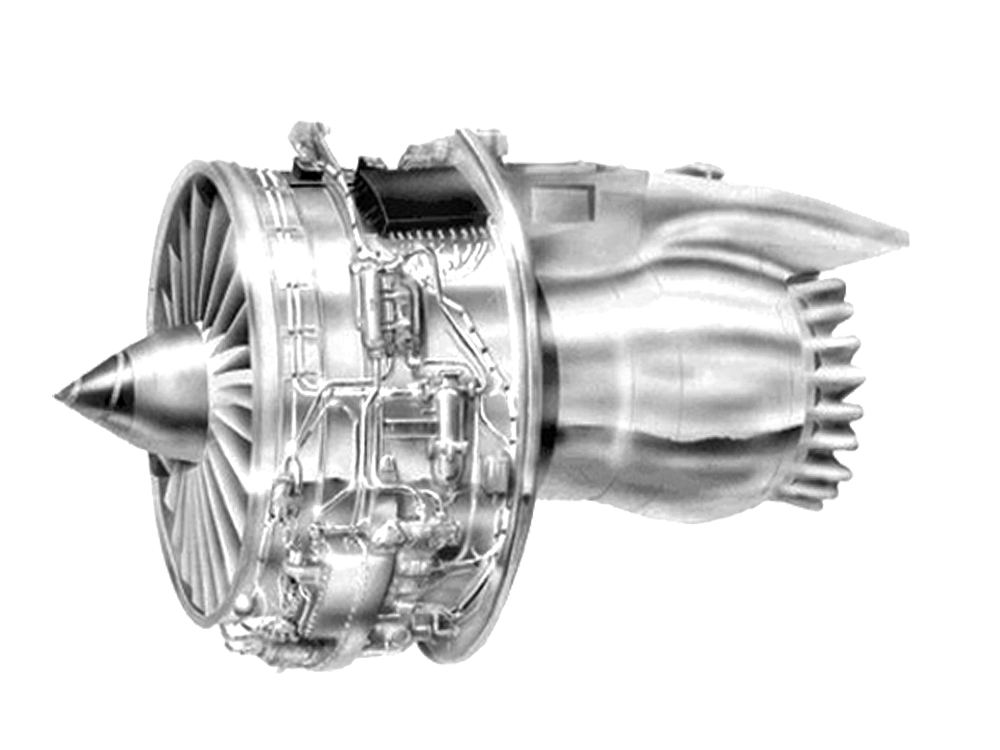

Engine maintenance capabilities across CF34-8, CFM56-5 & 7 and RB211-524 platforms, including;

CF34-8

- Lease returns inspection

- Maintenance Programs C-Check / MPD Tasks

- Engine module changes

- Airworthiness Directive (AD) and Service Bulletin (SB) Compliance

- LRU Removal and Replacement (Gearbox etc.)

- QEC Swap / Conversions

- Engine Teardown

- Part Identification / Packaging / ERP – Tracking & Inventorying

- Engine Storage / Preservation programs

- Sealed Engine Wrapping

- Boroscope Inspections

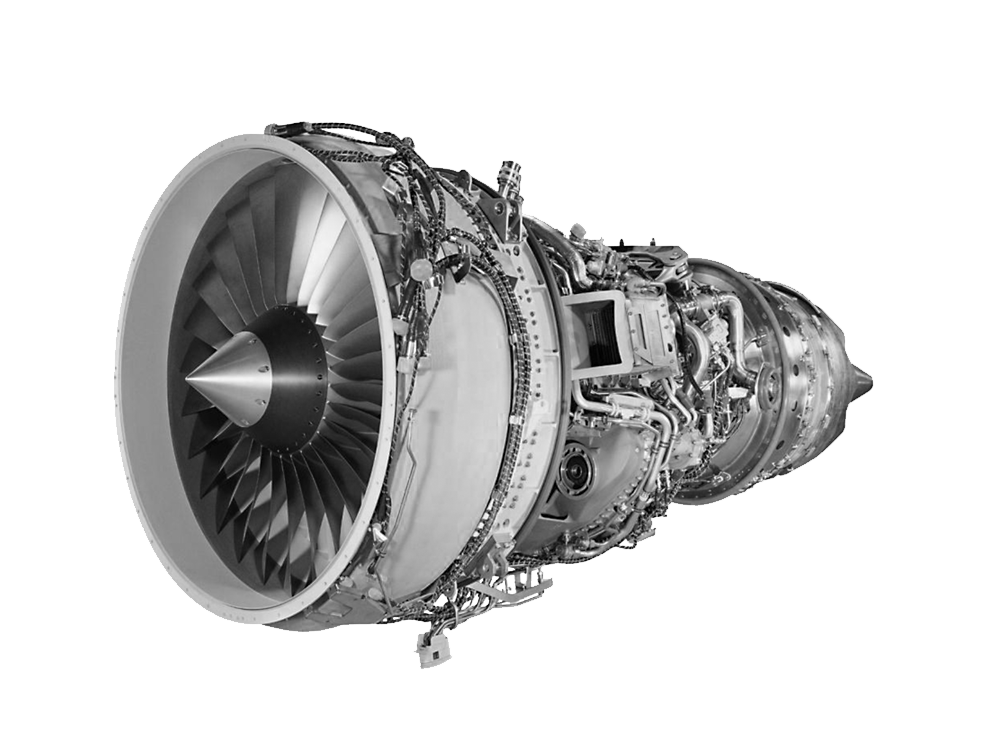

CFM56-5 & CFM56-7B

- Engine Teardown

- Part Identification / Packaging / ERP – Tracking & Inventorying

- LRU Removal / Checks

- End of Life Programs

- Engine Storage / Preservation programs

- Sealed Engine Wrapping

- Boroscope Inspection

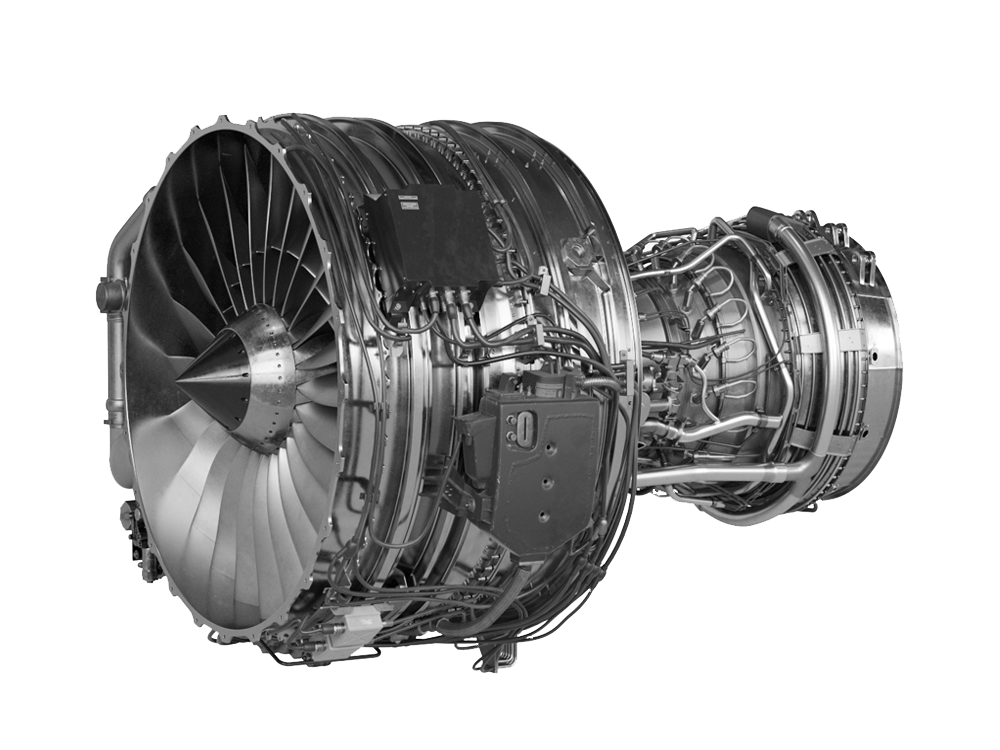

RB211-524

- Lease returns inspection

- Maintenance Programs C-Check / MPD Tasks

- Engine module changes

- LRU Removal and Replacement (Gearbox etc)

- QEC Swap / QEC Conversions

- Airworthiness Directive (AD) and Service Bulletin (SB) Compliance

- Engine Teardown

- End of Life Programs

- Part Identification / Packaging / ERP – Tracking & Inventorying

- Sealed Engine Wrapping

- Engine Storage / Preservation programs

- Boroscope Inspections

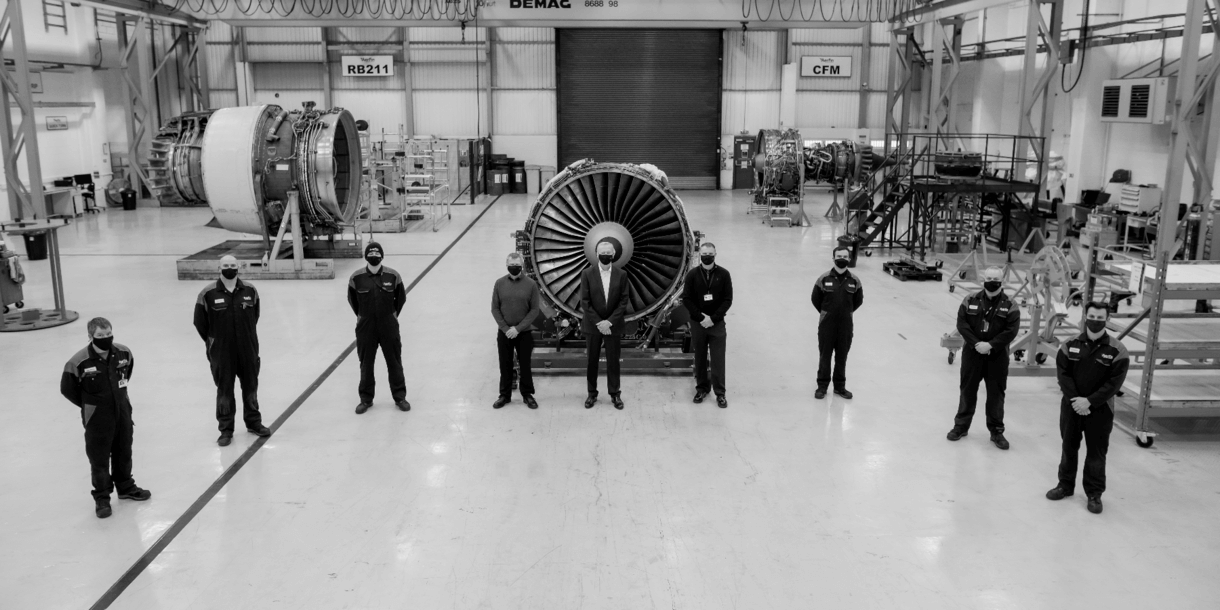

Explore our Facility

Further complementing our engine maintenance activity, our EASA Part 145, FAA and CAA Part 145 approved, temperature and humidity monitored facility is complete with a 10-tonne gantry overhead crane, a fire detection system and has the capacity to store up to 45 large fan engines or 55 small fan engines, or a combination of both.